The comparison between different manufacturing methods

Formative Manufacturing

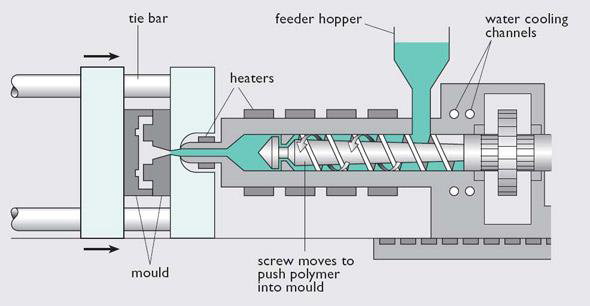

This is typical of high volume production and requires an expensive mold to produce the products. Injection molding, casting, stamping and forging are all means of formative manufacturing.

• Large initial investment in tooling (molds)

• Ideal for high volumes of the same part

• Can produce at a low price after initial investment recovered

The large upfront investment means high volumes need to be produced and sold in order to recover costs. These molds/tooling can be complicated to design and therefore very expensive. Molds often come from overseas.

Subtractive Manufacturing

Subtractive manufacturing is when material is taken away from a block of solid material (a blank), such as metal, wood, plastic etc. CNC milling, turning (lathe), drilling and

cutting are the methods used to remove the excess material.

• Ideal for simple geometries at low mid volumes

• Produces waste material

• Very few material restrictions

• Computer Aided Manufacturing (CAM) required which adds time & cost This can be a very cost effective method of production, given the appropriate design.

Additive Manufacturing (3D Printing)

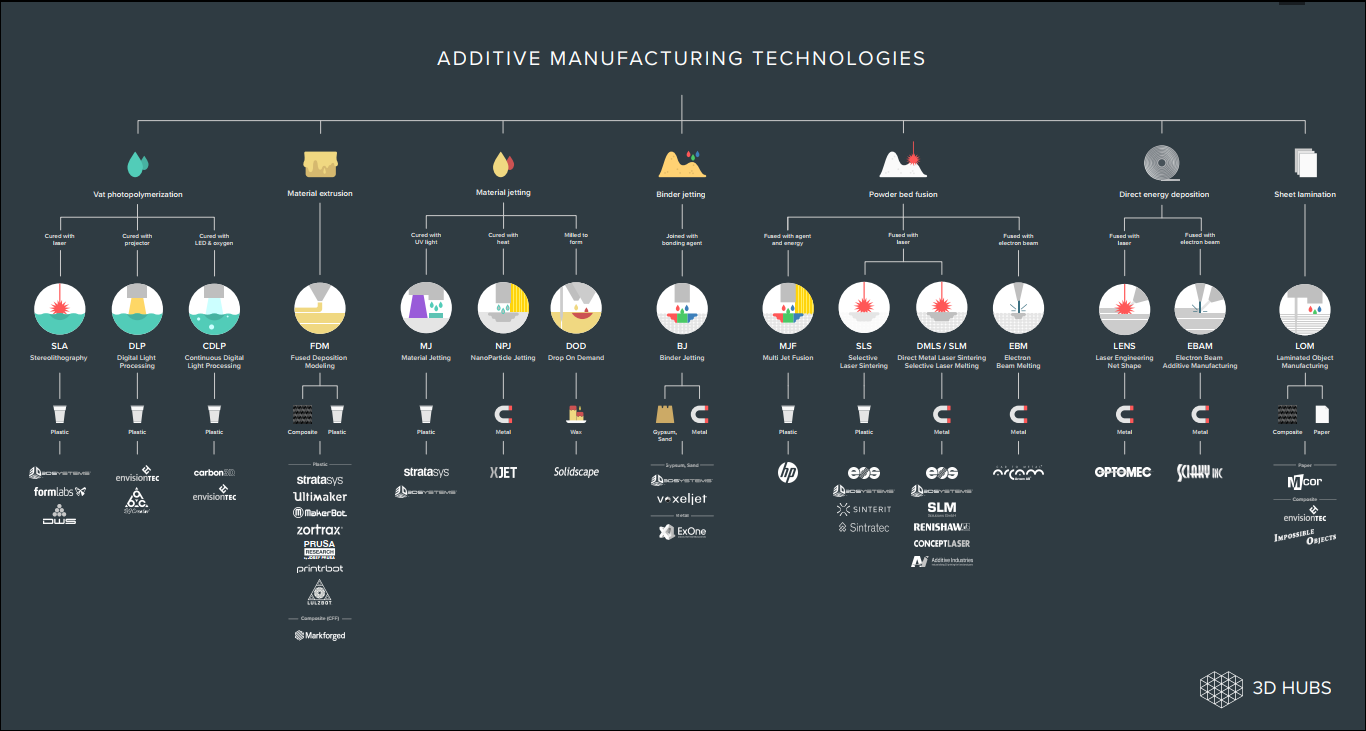

3D printing fills in the gaps of the above methods. It is a process of adding one layer at a time, building up a part in an additive ’ process. There are many types of 3 D printing, with FDM (Fused Deposition Modelling) /FFF (Fused Filament Fabrication) and SLA (Stereolithography) being the most commonly used.

• Ideal for low volume or one of prototypes

• Can create complex designs that formative and subtractive cannot any geometry possible!

• Very low start up cost ( 3D printers can cost as little as $ 300)

3D printing is thus ideal for rapid verification, rapid prototyping and low volume production (we recommend no more than 100 parts). There are also a wide range of qualities of 3D prints depending on the quality of the printer and materials used.

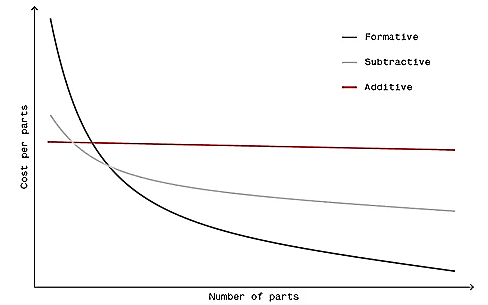

Comparison of Costs

Each method of manufacturing has different associated costs. Formative manufacturing is high cost for small volumes of parts, but once production ramps up, it s the most cost

effective method. Subtractive is similar, but less expensive at first and not as cheap as formative. The cost of 3D printing remains pretty much the same over all volumes.

Reference

https://kuunda kuunda3d.com/ 2018/02/08/3d printing as manufacturingmanufacturing/

prepared by: tika3d

Instagram: https://www.instagram.com/tika3d/

telegram channel: https://t.me/tika3d

e-mail: [email protected]

net3d ID: @n-mosleh